Welcome to our comprehensive guide on how to install push nuts! Push nuts, also referred to as push-on fasteners or speed nuts, are widely used in various industries for their efficient and secure installation capabilities.

Whether you’re a DIY enthusiast or a professional, understanding the correct installation process for push nuts is essential.

In this guide, we will provide you with step-by-step instructions on how to install push nuts, along with valuable insights into push nut installation tools, push nut washers, and even how to remove push nuts and rivet nuts.

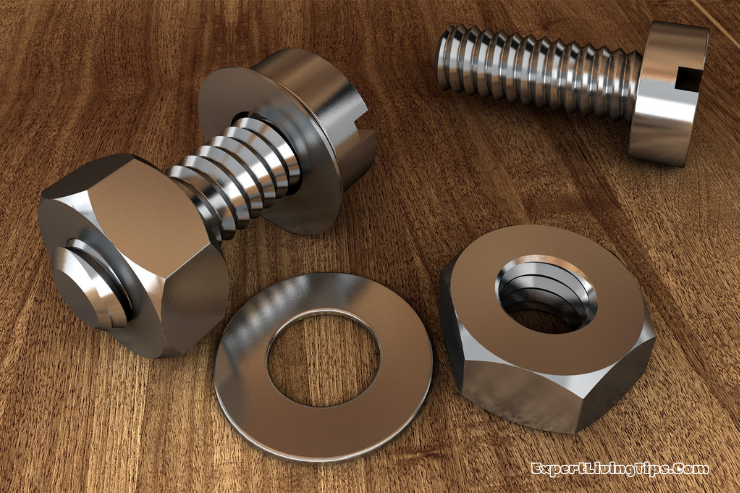

Push nuts are mechanical fasteners designed to create a reliable grip on threaded shafts or studs. These fasteners feature inward-facing, spring-like prongs that allow them to be easily pressed onto the threaded shaft.

Once installed, the prongs create a firm grip, preventing the push nut from loosening or coming off.

To ensure successful installation, it’s important to gather the necessary tools and materials. You will need push nuts of the appropriate size and quantity, a push nut installation tool, and a screwdriver or pliers for removal purposes, if necessary.

Additionally, lubricant can be used to facilitate easier installation, although it is optional.

In the following sections, we will provide you with a detailed step-by-step guide to installing push nuts correctly. We will cover everything from preparing the work area to selecting the proper push nut size and securely placing the push nut on the threaded shaft.

We will also explore the benefits of using push nut installation tools and push nut washers to enhance the overall installation process and increase the stability of the fastening.

Furthermore, in the realm of home improvement, we understand that there may be instances where push nuts or rivet nuts need to be removed.

Therefore, we will also share detailed instructions on how to safely remove push nuts and rivet nuts without causing any damage to the surface or the shaft.

By the end of this comprehensive home improvement guide, you will have a solid understanding of how to install push nuts effectively, empowering you to confidently tackle any project that requires secure and reliable fastening.

So, let’s dive into the step-by-step instructions and explore the various aspects of push nut installation, ensuring your success in any future home improvement endeavors!

Powerful Step-by-Step Instructions: How to Install Push Nuts Like a Pro

1. Understanding Push Nuts

Push nuts, also known as push-on fasteners or speed nuts, are mechanical fasteners commonly used in a wide range of applications. They are designed to create a secure grip on threaded shafts or studs without the need for additional tools or external fasteners.

Push nuts consist of a circular body with inward-facing, spring-like prongs. These prongs are strategically positioned to grip onto the threads of the shaft or stud when pressure is applied. The inward-facing prongs provide a tight hold, preventing the push nut from coming loose or rotating.

These fasteners are typically made from durable materials such as steel or stainless steel, which ensures their strength and longevity. They are available in various sizes to accommodate different shaft diameters and thread pitches.

The primary advantage of push nuts is their ease of installation. They can be quickly and securely installed by simply pressing them onto the threaded shaft using hand pressure or a push nut installation tool. Once in place, the push nuts provide a reliable fastening solution, eliminating the need for additional nuts, bolts, or washers.

Push nuts find applications in a wide range of industries, including automotive, electronics, furniture, and appliances. They are commonly used to secure components, panels, brackets, or other parts that require a secure and vibration-resistant fastening method.

It is important to select the appropriate push nut size that matches the diameter and thread pitch of the shaft or stud. Using an incorrect size can result in an improper fit and compromise the effectiveness of the fastening.

In the next sections of this guide, we will explore the essential tools and materials needed for push nut installation, provide a step-by-step guide on how to install push nuts correctly, discuss the benefits of push nut installation tools and push nut washers, and offer instructions on how to remove push nuts and rivet nuts if necessary.

By understanding the purpose and functionality of push nuts, you will be better equipped to utilize them effectively in your projects, ensuring secure and reliable fastening solutions.

Before you begin the installation process for push nuts, it’s important to gather the necessary tools and materials. Having these items on hand will ensure a smooth and efficient installation.

Here are the essential tools and materials you’ll need:

Push Nuts: Acquire push nuts in the appropriate size and quantity for your project. Push nuts are available in various sizes to match different shaft diameters and thread pitches. Be sure to select the push nuts that are compatible with your specific application.

Push Nut Installation Tool: While it is possible to install push nuts using your fingers, a push nut installation tool can make the process easier and more efficient, especially when working with smaller or hard-to-reach spaces.

The installation tool provides better control and reduces the risk of slippage or damage during installation. You can find push nut installation tools at hardware stores or online.

Screwdriver or Pliers (for Removal, if necessary): Sometimes, push nuts may need to be removed or replaced. In such cases, a flathead screwdriver or pliers can be helpful.

These tools will allow you to apply outward pressure and gently pry the push nut away from the threaded shaft or stud. Exercise caution during the removal process to avoid damaging the surface or the shaft.

Lubricant (Optional): While not essential, using a lubricant can make the installation process smoother, especially when dealing with tight or stubborn push nuts.

Apply a small amount of lubricant, such as WD-40 or a similar product, to the threads of the shaft before installing the push nut. This can help reduce friction and make it easier to push the nut into place.

By making sure you have all the essential tools and materials prepared, you will be fully equipped to commence the process of how to install push nuts.

The push nuts, along with the installation tool, as well as any supplementary items such as screwdrivers or pliers, must be readily accessible.

Once everything is set, you can confidently proceed with the step-by-step push nut installation guide, which will be comprehensively covered in the subsequent sections, emphasizing the importance of knowing how to install push nuts for a successful outcome.

2. How to Install Push Nuts: Simplified Step-by-Step Instructions

Follow these detailed step-by-step instructions to correctly install push nuts

Step 1: Prepare the Work Area

Before starting the installation process, ensure that the work area is clean and free from any debris or obstructions. This will provide a clear and safe space for installing the push nuts.

Step 2: Gather the Tools and Materials

Make sure you have all the necessary tools and materials within reach. These include push nuts, a push nut installation tool, a screwdriver or pliers (for removal if necessary), and optional lubricant for easier installation.

Step 3: Select the Proper Push Nut Size

Choose the push nut size that matches the diameter and thread pitch of the shaft or stud you are working with. Using the correct size is crucial for a secure and effective installation.

Step 4: Position the Push Nut

Hold the push nut between your thumb and forefinger, ensuring that the prongs are facing inward toward the shaft. Align the push nut with the threaded shaft or stud.

Step 5: Apply Pressure to Install the Push Nut

Using your fingers or a push nut installation tool, apply firm and even pressure to the push nut. Push it downward along the threaded shaft, making sure it slides smoothly into place.

Step 6: Verify Secure Installation

Check that the push nut is securely seated against the surface and has a firm grip on the threads. Give it a gentle tug to ensure it doesn’t come loose. Repeat the installation process for any additional push nuts required.

Step 7: Optional Lubrication

If you encounter resistance during installation, you can apply a small amount of lubricant to the threads of the shaft. This can help reduce friction and facilitate easier installation. However, be cautious not to use excessive lubricant that may cause the push nut to slip or loosen over time.

Step 8: Repeat for Multiple Push Nuts

If your project requires the installation of multiple push nuts, repeat steps 4 to 7 for each one. Ensure they are aligned properly with the threaded shafts and seated securely.

Step 9: Final Check and Adjustments

Once all push nuts are installed, visually inspect them to ensure they are evenly placed and properly seated. Make any necessary adjustments if you notice any loose or misaligned push nuts.

By following these step-by-step instructions, you can successfully learn how to install push nuts in your project.

Remember to choose the correct size, apply even pressure, and verify a secure installation. The next sections will provide additional information on how to install push nuts, including push nut installation tools, push nut washers, and removing push nuts and rivet nuts.

This will further expand your knowledge on working with these fasteners, enhancing your proficiency in how to install push nuts.

3. Exploring Push Nut Installation Tools

Push nut installation tools are handy devices that can greatly simplify and enhance the process of installing push nuts. These tools provide better control, improved efficiency, and reduce the risk of slippage or damage during installation.

Let’s explore some commonly used push nut installation tools:

Push Nut Pliers: Push nut pliers are specifically designed to assist in the installation of push nuts. They feature a unique jaw design that grips the push nut securely and applies even pressure while pushing it onto the threaded shaft.

Push nut pliers provide better control and ensure a more accurate installation, especially in tight or hard-to-reach spaces.

Push Nut Installation Tool: Push nut installation tools are handheld devices specifically designed for installing push nuts. These tools typically consist of a handle and a push nut holder or driver.

The push nut holder securely holds the push nut in place while allowing you to apply pressure to push it onto the threaded shaft. Push nut installation tools come in various sizes to accommodate different push nut diameters.

Push Nut Setter: A push nut setter is a specialized tool used for installing push nuts. It consists of a handle with a recessed tip that matches the shape and size of the push nut.

To install a push nut, simply place it onto the recessed tip of the push nut setter, align it with the threaded shaft, and press down firmly.

The push nut setter ensures precise and controlled installation, minimizing the risk of damage to the push nut or the workpiece.

Socket Wrench Adapter: In some cases, a socket wrench adapter can be used as a makeshift push nut installation tool.

his adapter fits into a socket wrench, allowing you to apply controlled pressure while installing the push nut. While not as specialized as other push nut installation tools, a socket wrench adapter can be a convenient option if you already have one on hand.

When choosing a push nut installation tool, consider the size and style of the push nuts you are working with, as well as the specific requirements of your project.

Using a push nut installation tool can streamline the installation process, increase efficiency, and help achieve more consistent and reliable results.

Remember to follow the manufacturer’s instructions for the specific installation tool you choose and ensure that it is compatible with the push nuts you are using. With the right tool in hand, you can confidently install push nuts with ease and precision.

4. Utilizing Push Nut Washers for Enhanced Security

Push nut washers, also known as thrust washers, can be used in conjunction with push nuts to provide enhanced security and stability.

These washers are designed to evenly distribute the load and minimize the risk of push nut slippage or loosening.

Here’s how you can utilize push nut washers for enhanced security:

Select the Proper Push Nut Washer

Choose push nut washers that are compatible with the size and shape of your push nuts. Push nut washers come in various sizes and thicknesses, so ensure you select ones that match the dimensions of your push nuts.

Position the Push Nut Washer

Before installing the push nut, place the push nut washer on the threaded shaft or stud. The washer should be positioned between the surface and the push nut.

Install the Push Nut

Proceed with the installation of the push nut by following the step-by-step instructions mentioned earlier. As you apply pressure to install the push nut, the push nut washer will create a more stable and even surface for the push nut to grip onto.

Verify Secure Installation

Once the push nut is installed, visually inspect it to ensure that it is seated securely against the washer and the surface. Give it a gentle tug to check for any signs of loosening.

The push nut washer should provide an additional layer of security, reducing the risk of the push nut coming loose due to vibrations or external forces.

Push nut washers are particularly useful in applications where there is a need for increased stability and resistance to vibration.

They are commonly used in automotive, electronics, and furniture industries, among others, to secure components, panels, or brackets that are subjected to constant movement or stress.

When selecting push nut washers, consider factors such as the material (typically steel or stainless steel), thickness, and the size compatibility with your push nuts and threaded shafts.

Using push nut washers in conjunction with push nuts will provide added security, ensuring a more reliable and durable fastening solution.

Remember to follow the manufacturer’s recommendations and guidelines for the specific push nut washers you choose to ensure optimal performance and installation.

5. How to Remove Push Nuts and Rivet Nuts

There may be instances when you need to remove push nuts or rivet nuts, whether for repairs, adjustments, or disassembly.

Here is a step-by-step guide on how to safely remove push nuts and rivet nuts:

5.1 Removing Rivet Nuts

Identify the Rivet Nut

Identify the rivet nut that needs to be removed. Pay attention to the type of rivet nut and the specific installation method used, as removal techniques may vary.

Determine Removal Method

There are different methods to remove rivet nuts, depending on the specific design and installation technique.

Some common removal methods include:

a. Drilling Method: Use a drill bit slightly larger than the rivet nut’s internal diameter. Carefully drill through the center of the rivet nut until it is completely detached from the surface.

b. Splitting Method: Utilize a specialized splitting tool or a chisel and a hammer. Make a precise cut or split in the rivet nut, then use the chisel to pry it open and remove it from the surface.

c. Removal Tool: Some rivet nuts may require specific removal tools designed for their unique installation method. These tools help reverse the installation process by collapsing or unscrewing the rivet nut.

Follow Removal Technique

Based on the type of rivet nut and the chosen removal method, carefully follow the appropriate technique to remove the rivet nut from the surface. Ensure that you exercise caution and take necessary safety precautions when using power tools or striking tools.

Clean the Area

After removing the push nut or rivet nut, clean the area around the threaded shaft or stud. Remove any remaining debris or residue to ensure a clean surface for future installations or repairs.

By following these step-by-step instructions, you can safely and effectively remove push nuts and rivet nuts when needed.

Always prioritize safety, use the appropriate tools, and take care to avoid damaging the surrounding components or the threaded shaft during the removal process.

6. Conclusion

Congratulations on completing our comprehensive guide on how to install push nuts. Throughout this guide on how to install push nuts, we covered everything from understanding push nuts and gathering the necessary tools and materials to providing a step-by-step installation process.

In addition to the step-by-step guide on how to install push nuts, we also explored push nut installation tools, the use of push nut washers for enhanced security, and the techniques for removing push nuts and rivet nuts.

By mastering the process of how to install push nuts, you can confidently tackle various projects that require secure and efficient fastening using push nuts.

Whether you are working on automotive repairs, electronics assembly, furniture construction, or any other application, the knowledge and skills you have gained from this guide on how to install push nuts will serve you well.

Always remember to select the proper push nut size, prepare the work area adequately, and apply firm and even pressure during the installation of push nuts.

For added convenience and precision in the process of how to install push nuts, consider using push nut installation tools. Moreover, if you need additional security, incorporating push nut washers can provide enhanced stability.

When it comes to the removal of push nuts, follow the appropriate techniques to safely remove push nuts and rivet nuts without causing any damage.

As you continue to work with push nuts, always refer to manufacturer instructions and guidelines specific to your project or application to ensure successful installation.

Throughout the installation and removal processes, safety should be a top priority. Always exercise caution and take appropriate safety measures.

We hope this guide on how to install push nuts has been informative and helpful to you. By mastering the installation and removal of push nuts through this guide, you can confidently handle fastening tasks and ensure the security and longevity of your future projects.

Best of luck with your future endeavors!

Reference Resources:

Fantastic post! You have a unique way of bringing the subject to life.